Dewalt tools, including cordless drill units,are well-familiar among professionals for durability and delivering reliable performance. However, you cannot say that these drills won’t face any mechanical issues.

Cordless ones face much fewer difficulties than corded ones, still, at some point of the product lifespan, you may need to send it to the service center. If the drill is under warranty, you don’t need to worry regarding it. But, once the warranty period ends, simple repairing can cost a considerable amount of money.

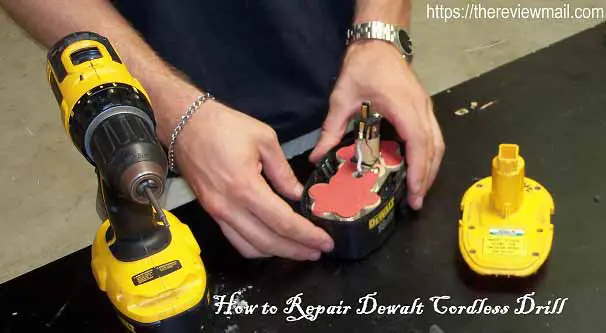

With that being said, knowing how to repair Dewalt cordless drill comes quite beneficial, especially if you have other drills or cordless power tools.

Table of Contents

How to Repair Dewalt Cordless Drill?

Let’s have a look at some of the most common issues that can occur to these drill machines and their possible solutions without using any fancy instruments.

Battery Isn’t Charging

One of the most common scenarios of owning cordless power tools is when the battery doesn’t seem to charge or hold the charge for a minimum time period. Once you unplug the charger, the drill doesn’t turn on.

Possible Solutions

- Make sure the power source connected to the plug is well-functional. Try plugging-in to another power outlet to confirm whether the problem is with the battery itself or not.

- When the battery doesn’t hold the charge for a minimum period of time, this indicates that the battery needs to be replaced. To prevent this from happening in the first place, be sure not to drain the battery fully, and charge it to 90%. Charging this way will increase the overall battery cycle.

- Check if the fuse in the charger is okay or not. If it’s blown, you need to replace the fuse, not the entire charger itself.

- When the charger takes a lot of wear and tear, and there are too many broken parts all over it, most likely, the charger isn’t able to properly charge the battery. Replacing the charger should fix the issue if this is the case.

Drill Won’t Turn on

Quite a few times, the drill doesn’t turn on after pressing the trigger. There can be several reasons behind it.

Possible Solutions

- In most cases, a low or dead battery is the reason for this. When the battery is low, the tool can work slowly or not work at all. Consider fully charging the battery.

- Another reason for this is the attached brushes. When the brushes get old or accumulate a lot of dirt, it doesn’t let the drill turn on. Consider removing it, and giving it a thorough cleaning. If this doesn’t resolve the issue, you will need to replace these brushes.

- As the motor is the main power source of a drill machine, if this component doesn’t work, there will be no hope for the drill to turn on. Perform regular maintenance, and see if this fixes the issue. If the motor is burned out, then consider replacing the motor.

- Probably you won’t need to replace the motor in the first place. Sometimes, when the connections of the motor get dirty, this doesn’t let the motor fully function or turn on. Consider cleaning the connections if this is the case.

Dewalt Cordless Drill Chuck Problems

Dewalt Drill Chuck Wobbling fix

The chuck is the part that holds the drill bit in place and ensures smooth and flawless drilling. You can come across a wobbling chuck issue for quite a few reasons. However, compared to other repairs, dealing with the chuck is fairly easier.

Possible Solutions

- Chuck is located underneath where you place the bit. The most common reason for wobbling is when the chuck is loose. To fix this, consider rotating the chuck clockwise, and the chuck should no longer wobble after that.

- Dirt and dust particle build-ups can block the chuck, which results in a loose chuck, and not being able to get tightened. In this case, consider removing the chuck and thoroughly clean the build-up from it. Then install as it was — this should fix the issue.

- When the chuck gets exposed to water or other elements that cause corrode and corrosion, you can expect such an issue to occur. If this is the case, you need to replace the chuck.

Gears Making a Squeaky Noise

The drill functions well, and the performance is as it’s used to be. However, the gears can make some annoying noise while drilling.

Possible Solutions

- Clutch is most likely the thing causing the issue. This is the component that allows the user to adjust the torque settings. When the clutch is broken or misplaced, the drill makes such noise. Replacement is the only solution to this issue.

Drill Is Stuck in Reverse

It seems unusual that the drill spins in a reverse direction. Luckily, it requires easy repairing with any need of tools.

Possible Solutions

- When the directional switch is somehow engaged to reverse direction, the issue occurs. This switch is located above the trigger. Consider switching it to the opposite direction. The drill should spin forward after that.

- The reverse switch often gets stuck due to dirt and grime build-up, which causes it to only drill in the reverse direction. Thoroughly clean the switch and the area around it.

- If the reverse switch is broken, replacement is the only solution left. replace the Gearbox.

Cordless Drill Maintenance Tips

If the drill is well-maintained, you are less likely to face trouble using the tool. Be sure to follow the following maintenance tips periodically to keep the drill in a good shape.

- Always use the right drill bit that meets the chuck size.

- Use sharp bits. Drilling with blunt bits requires putting great force onto the drill, which often breaks certain parts of the machine.

- When you engage in a large drilling project, be sure to take a break in between drilling sessions. This practice will increase the longevity of the drill unit.

- Try not to overheat the drill. The tool overheats when you try to drill extremely hard materials. Don’t drill such materials for a long time.

- If you have multiple drill units, consider hanging them on the wall with a vinyl-covered hook. This is much safer than keeping the tools on the table. The tools won’t fall off the table and will give you easy access to them whenever you need them.

Final Words

Once you learn how to repair Dewalt cordless drill, you can also use the same technics when it’s about other cordless power tools of a similar category. Cordless impact drivers, nail guns, etc., are the same when it’s about basic troubleshooting and repairing.

Related Post:

Best dewalt cordless drill review

Williams Kane is a blogger and writer. He’s passionate about writing and connecting with the community, especially when it comes to sharing his ideas through writing.

I am a versatile author with a passion for exploring a wide range of topics on our multi-niche website. With a background in research and a love for writing, I bring a unique blend of expertise to our platform.

My journey began in the world of science, where I earned a degree in biology and developed a deep fascination for the natural world. This background enables me to delve into topics related to ecology, environmental conservation, and the wonders of the animal kingdom.

However, my curiosity knows no bounds, and I have ventured into various other niches as well. From technology trends and digital innovations to health and wellness tips, I strive to provide well-researched and engaging content that informs and entertains our diverse audience.

Furthermore, my dedication to staying current with the latest developments in each niche ensures that our readers receive up-to-date and reliable information. Whether it’s deciphering complex scientific concepts or simplifying tech jargon, I take pride in making complex subjects accessible to all.

Join me on our multi-niche journey, where we explore the depths of knowledge and share insights on a multitude of topics to inspire, educate, and entertain.