No, you absolutely do not need a table saw to start woodworking. Many fantastic projects can be built using safer, cheaper, and smaller tools like a circular saw with a straightedge guide. A table saw is a powerful upgrade for making fast, repetitive, and precise cuts, but it is not a requirement for beginners.

Walking into a workshop for the first time can feel a little overwhelming. You see all these large, impressive machines. The one that often stands out is the table saw. It looks powerful. It looks professional. And it looks expensive. So, you start to wonder, “Do I really need one of those to get started?” It’s a question every new woodworker asks.

The internet is full of strong opinions. Some say it’s the heart of the workshop. Others warn of its dangers. It can be confusing and might even stop you from starting at all. But don’t worry. We are going to clear things up. Together, we will look at what a table saw does, explore great alternatives, and help you decide if and when this tool is right for you and your workshop.

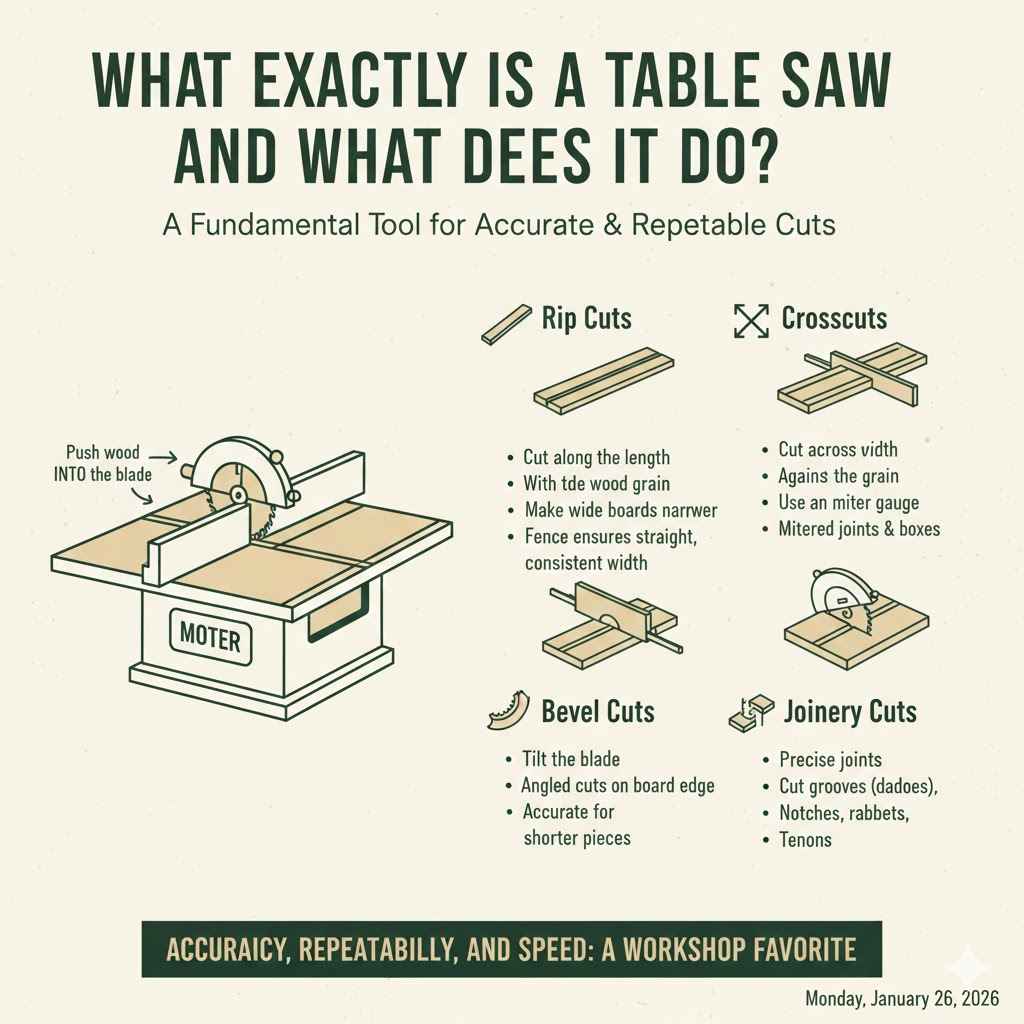

What Exactly Is a Table Saw and What Does It Do?

Let’s demystify this machine. A table saw is actually a very simple tool in concept. It is a circular saw blade that pokes up through a slot in a large, flat metal table. An electric motor spins the blade at high speed. Instead of moving the saw over the wood (like you do with a circular saw), you push the wood across the table and into the blade.

This simple design makes it incredibly good at a few key jobs. Its main superpower is making perfectly straight cuts, over and over again. It does this with the help of a guide called a “fence” that runs parallel to the blade.

Here are the main types of cuts a table saw excels at:

- Rip Cuts: This is the table saw’s number one job. A rip cut is a cut made along the length of a board, going with the wood grain. This is how you take a wide board and make it narrower. The fence ensures the cut is perfectly straight and the width is consistent from start to finish.

- Crosscuts: This is cutting a board across its width, or against the grain. While a miter saw is often better for this, a table saw can do it accurately using a “miter gauge” that slides in a slot on the table.

- Bevel Cuts: By tilting the saw blade, you can make angled cuts along the edge of a board. This is useful for creating joints that come together at an angle, like in a mitered box.

- Joinery Cuts: Table saws are fantastic for cutting precise joints that help hold your projects together. With special blades or jigs, you can cut grooves (dadoes), notches (rabbets), and tenons, which are all fundamental building blocks of furniture and cabinetry.

The three words to remember for a table saw are accuracy, repeatability, and speed. Once you set the fence, you can cut ten boards to the exact same width without ever measuring again. This is what makes it a workshop favorite for serious hobbyists and professionals.

The Big Question: Can You Do Woodworking Without a Table Saw?

Yes. A thousand times, yes! You can absolutely build beautiful, sturdy, and impressive woodworking projects without ever owning a table saw. For centuries, craftsmen built masterpieces with nothing more than hand saws, chisels, and planes. While we have more options today, the principle is the same: the skill is more important than the machine.

Many beginners feel pressured to buy a table saw right away, thinking it’s a mandatory entry ticket to “real” woodworking. This isn’t true. In fact, starting without one can be a huge benefit.

Starting with simpler tools forces you to learn the fundamentals of wood, measuring, and cutting. It builds a strong foundation of skills. It is also much safer, cheaper, and requires far less space. You can set up a great beginner workshop in a corner of your garage with a few versatile hand-held power tools.

Top Table Saw Alternatives for Beginners

So, if you don’t need a table saw, what should you use instead? You have some fantastic, affordable, and safer options that can handle most of the cuts you’ll need for your first dozen projects.

The Mighty Circular Saw

The circular saw is perhaps the most underrated tool for precision woodworking. Most people think of it as a rough construction tool, but with a good blade and a simple guide, it can be just as accurate as a table saw, especially for breaking down large sheets of plywood.

The key to accuracy is a straightedge guide. You clamp a straight piece of wood or metal to your workpiece and run the edge of the saw’s baseplate against it. This guarantees a perfectly straight cut every time.

You can even make your own custom saw guide, often called a track saw jig. Here’s how:

- Get a piece of 1/4″ plywood about 12 inches wide and 4 feet long.

- Get a piece of 3/4″ plywood or MDF that is perfectly straight, about 3 inches wide and 4 feet long.

- Glue and screw the narrow strip onto the wider base, about 4 inches in from one edge. Make sure it’s perfectly parallel.

- Place your circular saw on the base with its edge plate running against the fence you just attached.

- Run the saw all the way down the guide. This will trim the excess off the base.

Now, the edge of your guide is perfectly aligned with your saw blade’s cutting path. To make a cut, just line up the edge of the guide with your pencil mark and clamp it down. It’s a simple, cheap, and incredibly effective system.

The Track Saw (The Circular Saw’s Big Brother)

A track saw, also known as a plunge saw, is a refined version of the circular saw and guide system. It’s a specially designed circular saw that rides on a dedicated metal track with a non-slip backing. The track has a rubber splinter guard right on the edge, which shows you exactly where the blade will cut.

You simply lay the track on your cut line and make the cut. The results are incredibly clean, precise, and straight. Track saws are the best tool for cutting down large sheets of plywood or MDF, a task that can be awkward and dangerous on a table saw, especially for one person.

While more expensive than a regular circular saw, a good track saw is often cheaper than a good table saw and takes up almost no space. For many hobbyists working in small shops, a track saw is a better investment.

The Jigsaw and Bandsaw

A table saw only cuts in straight lines. But what about curves? That’s where the jigsaw and the bandsaw come in. A jigsaw is a handheld tool with a small reciprocating blade that is perfect for cutting curves, circles, and other custom shapes. A bandsaw is a stationary tool with a long, continuous blade that runs on two wheels. It is the master of cutting precise, smooth curves and can also be used to slice boards into thinner pieces, a process called resawing.

The Miter Saw (The Crosscut King)

While a table saw can crosscut, a miter saw is designed specifically for that job and does it better, faster, and often more safely. A miter saw has a circular saw blade mounted on a pivoting arm that you pull down to cut the wood. It excels at cutting pieces to the perfect length and at precise angles (miters). If you are making picture frames, door trim, or any project that requires repeated, accurate crosscuts, a miter saw is an invaluable tool.

Hand Saws (The Old-School Approach)

Don’t forget about hand tools! A good quality handsaw can be a joy to use. Modern Japanese pull saws, in particular, are incredibly efficient and accurate. They cut on the pull stroke, which gives you more control and results in a very thin, clean cut. They are quiet, produce no dust clouds, and are perfectly safe. Learning to use a handsaw well is a rewarding skill that connects you to the craft in a unique way.

Comparing Your Options: Table Saw vs. The Alternatives

To help you decide, let’s put these tools side-by-side. This table gives a quick overview of what each tool is best for, along with its general cost and space requirements.

| Tool | Best For | Price Range (New) | Space Required | Beginner Friendliness |

|---|---|---|---|---|

| Table Saw | Repetitive rip cuts, joinery | $300 – $1500+ | Large (stationary) | Moderate (requires safety training) |

| Circular Saw + Guide | Straight cuts on any size board, affordability | $50 – $200 | Small (stores easily) | High (easy to learn) |

| Track Saw | Perfectly clean cuts on large panels (plywood) | $400 – $900 | Small (track can be hung on wall) | High (very intuitive) |

| Miter Saw | Fast, precise crosscuts and angled cuts | $150 – $600 | Medium (needs width clearance) | High (easy to use safely) |

| Hand Saws | Quiet, precise joinery, learning the craft | $30 – $100 | Minimal | Moderate (requires practice) |

When Should You Actually Buy a Table Saw?

Sooner or later, as your skills and projects grow, you might find that your current tools are holding you back. A table saw is a logical step up, but it’s a big one. It’s an investment in space, money, and your commitment to the hobby.

You’re Ready for a Table Saw If…

- You need to make many identical cuts. If you’re building a set of kitchen cabinets, a bookshelf with ten identical shelves, or face frames for furniture, the repeatability of a table saw will save you countless hours and improve your accuracy.

- You are working with lots of hardwood. Ripping a long, thick piece of maple with a circular saw can be challenging. A table saw’s power and stability make these cuts much easier and cleaner.

- You want to cut advanced joinery. While you can cut tenons and other joints by hand, a table saw with a good blade or a dado stack makes it fast, easy, and perfectly repeatable.

- Your workshop has the space. A table saw needs a lot of room. You need clearance in front, behind, and to the sides of the saw to handle large pieces of wood safely.

- Your budget allows for a good, safe saw. A cheap, poorly made table saw can be frustrating and dangerous. It’s better to save up for a quality machine with a reliable fence and modern safety features.

- You are committed to safety. This is the most important one. You must be willing to learn, respect, and consistently follow all safety rules for the machine. For more information, you can review this helpful table saw safety guide from OSHA.

Safety First: The Unspoken Rule of Table Saws

We cannot talk about table saws without a serious discussion about safety. According to the U.S. Consumer Product Safety Commission, table saws are responsible for tens of thousands of serious injuries every year. The most common danger is kickback, which happens when the wood gets pinched by the blade and is violently thrown back at the operator at over 100 miles per hour.

However, modern table saws have excellent safety features, and by following simple rules, you can operate one safely for a lifetime. If you choose to get a table saw, these rules are not optional.

- Use the Riving Knife and Blade Guard. The riving knife is a small piece of metal that sits behind the blade and prevents the wood from pinching, which is the primary cause of kickback. The blade guard covers the blade to protect your fingers. Never remove them.

- Use Push Sticks and Push Blocks. Never let your hands get within several inches of the blade. Use push sticks, push blocks, or other safety devices to guide the wood through the cut.

- Wear Safety Gear. Always wear safety glasses or a face shield. Avoid loose clothing, gloves, and jewelry that could get caught in the blade.

- Stand in a Safe Zone. Never stand directly behind the path of the blade. Stand slightly to the side, so if kickback does occur, the wood will fly past you, not into you.

- Pay Attention. Do not use the saw when you are tired, distracted, or in a hurry. Woodworking should be a calm and focused activity.

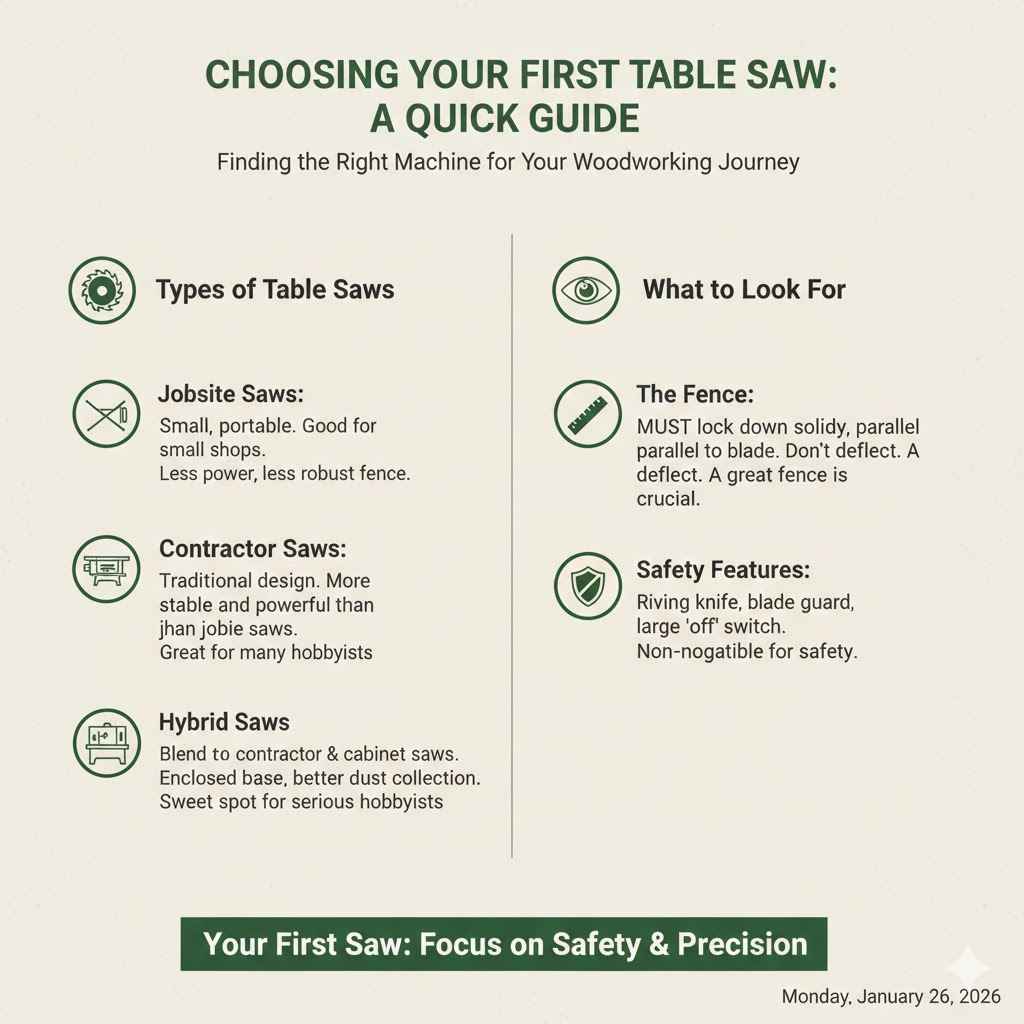

Choosing Your First Table Saw: A Quick Guide

If you’ve decided the time is right, choosing your first saw can be daunting. Here’s a quick breakdown of the types you’ll encounter.

Types of Table Saws

- Jobsite Saws: These are small, portable saws designed for contractors. They are lightweight and can be folded up for transport. They are a good option for very small shops, but their smaller motors and less robust fences can be limiting.

- Contractor Saws: This is a traditional design with the motor hanging off the back. They are a significant step up from jobsite saws in stability and power. Many great hobbyist saws fall into this category.

- Hybrid Saws: These saws blend the features of a contractor saw with the enclosed base and better dust collection of a cabinet saw. They are often the sweet spot for a serious hobbyist, offering great performance without the massive weight and power requirements of a cabinet saw.

What to Look For

When you’re shopping, don’t get distracted by horsepower. Focus on the two most important features for a beginner:

- The Fence: The fence is your guide for almost every cut. It must lock down solidly, perfectly parallel to the blade, and not deflect under pressure. A bad fence will make an expensive saw useless. A great fence can make a budget saw perform beautifully.

- Safety Features: A modern saw must have a riving knife that moves up and down with the blade. A blade guard is essential. A large, easy-to-reach “off” switch you can hit with your knee is also a critical feature.

FAQ: Your Table Saw Questions Answered

What is the most important safety feature on a table saw?

The riving knife. It is a piece of metal that sits directly behind the blade to prevent the wood from pinching as you cut, which is the main cause of dangerous kickback. It is the single most important safety device on a modern table saw.

Can I use a circular saw instead of a table saw?

Yes, absolutely. For making straight cuts, a circular saw paired with a straightedge guide or a track saw can be just as accurate as a table saw. It is an excellent, safe, and affordable alternative for beginners.

How much does a decent beginner table saw cost?

Expect to spend between $400 and $800 for a quality beginner table saw (a good jobsite or entry-level contractor saw). Cheaper saws often have unreliable fences and weaker motors that will cause frustration.

What’s the difference between a rip cut and a crosscut?

A rip cut is a cut made along the length of the board, parallel to the wood grain. A crosscut is a cut made across the width of the board, perpendicular to the wood grain.

Do I need a dado stack as a beginner?

No. A dado stack is a special set of blades used to cut wide grooves. As a beginner, you can make these cuts with multiple passes using a standard saw blade or with a router. It is an advanced accessory you can consider later.

Is a track saw safer than a table saw?

For cutting large sheet goods, yes. With a track saw, the wood stays stationary while you move the saw, which is much more stable and manageable. For general cutting, both tools are safe when used correctly with all safety features in place.

Where should I put a table saw in my small workshop?

Ideally, a table saw should be placed in the center of a shop to provide “infeed” and “outfeed” space for long boards. In a small shop, consider putting it on a mobile base so you can roll it out when needed and push it against a wall for storage.

Conclusion: Your Workshop, Your Choice

So, do you need a table saw for woodworking? The definitive answer is no. You can start this wonderful hobby and build amazing things with a few simple, affordable, and versatile tools. A circular saw, a good straightedge, a drill, and some clamps can take you a very long way.

Think of a table saw not as a starting point, but as a future upgrade. It’s a tool you earn your way into when your projects demand its unique strengths of speed and repeatability. By starting small, you build foundational skills, gain confidence, and learn what you truly enjoy making. Then, when the time is right, you will know exactly why you need a table saw and how to use it safely and effectively.

The most important tool in your workshop is you. Start with what you have, focus on the joy of creating, and build your skills one project at a time. The rest will follow.