A circular saw blade can last anywhere from a few hours to several months. The lifespan depends on usage, material, and blade quality.

Circular saw blades are essential tools for many woodworking and construction projects. But understanding how long a blade should last can save both time and money. Factors like the type of material you’re cutting, the frequency of use, and the quality of the blade all influence its lifespan.

Regular maintenance also plays a critical role. In this blog post, we’ll explore these factors in detail, helping you get the most out of your circular saw blade. Whether you’re a professional or a DIY enthusiast, this guide will provide valuable insights to maximize the efficiency and durability of your blades.

Factors Affecting Blade Lifespan

When you invest in a circular saw blade, you want it to last as long as possible. However, several factors can affect the lifespan of your blade. Understanding these factors can help you make informed choices and get the most out of your tool.

Material Quality

The quality of the blade’s material plays a significant role in its longevity. High-quality materials like carbide-tipped blades tend to last longer than cheaper, low-grade metals. They can handle more cuts before dulling.

Think about the materials you often cut. Frequent cutting of hardwood requires a high-quality blade. On the other hand, if you mostly work with softwood, a mid-range blade might suffice.

Frequency Of Use

How often you use your circular saw directly impacts blade lifespan. A blade used daily will wear out faster than one used occasionally. Keep track of your usage to estimate when the blade might need replacing.

Consider your projects. Are you a weekend warrior or a professional carpenter? Heavy, regular use demands more frequent blade replacements. Light, infrequent use means your blade will last longer.

Are you noticing your blade dulling quicker than expected? This might indicate overuse or improper maintenance. Regularly check and clean your blade to extend its life.

Credit: probladesoutlet.com

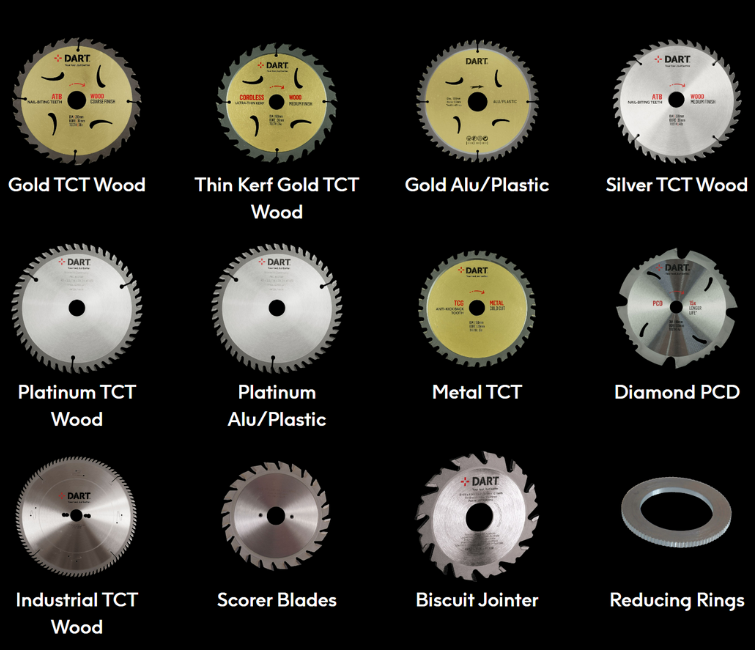

Types Of Circular Saw Blades

Choosing the right circular saw blade can impact its lifespan. Different types of blades serve various purposes. Knowing the types can help you get the most out of your blade. Let’s dive into the most common types.

Carbide-tipped Blades

Carbide-tipped blades are popular for their durability. They last longer than steel blades. Carbide tips are strong and handle tough materials well. These blades are great for wood, plywood, and particleboard. They stay sharp longer, reducing the need for frequent replacements. With proper care, carbide-tipped blades can last several months or even years.

Diamond Blades

Diamond blades are ideal for cutting hard materials. They excel at cutting concrete, tile, and stone. These blades have diamond particles on the edges. This makes them extremely tough and long-lasting. They can endure heavy use and still perform well. Diamond blades can last several months with regular use. Proper maintenance can extend their lifespan further.

Signs Of A Worn-out Blade

A well-maintained circular saw blade ensures smooth and precise cuts. Over time, even the best blades wear out. Knowing the signs of a worn-out blade helps maintain the quality of your work. Here are key indicators that your circular saw blade needs replacement.

Decreased Cutting Efficiency

One of the first signs is decreased cutting efficiency. The blade struggles to cut through materials. It feels slower than usual. This can lead to rough edges and imprecise cuts. If you notice your cuts are not as clean, it is time to check the blade.

Visible Wear And Tear

Another clear sign is visible wear and tear. Look closely at the blade. Check for broken or chipped teeth. Rust or discoloration also indicates wear. A worn blade can be dangerous. Replace it to ensure safety and quality cuts.

Proper Maintenance Techniques

Extending the life of a circular saw blade requires proper maintenance. Regular care ensures the blade performs at its best. Here are some crucial techniques for maintaining your circular saw blade.

Regular Cleaning

Dirt and debris can damage the blade. Clean the blade after each use. Use a soft brush or cloth to remove sawdust and residue. This prevents buildup and keeps the blade sharp.

A clean blade cuts better and lasts longer. Consider using a cleaning solution for stubborn grime. Make sure to dry the blade completely to avoid rust.

Proper Storage

Storing your blade correctly is vital. Keep the blade in a dry place. Moisture can lead to rust and corrosion. Use blade guards or cases for added protection.

Avoid stacking blades directly on top of each other. This prevents damage and keeps them sharp. Proper storage extends the life of your circular saw blade.

Sharpening And Replacement

Maintaining the sharpness of your circular saw blade is crucial for efficient cutting. Regular sharpening and timely replacement keep your blade in top condition. This ensures clean cuts and extends its lifespan.

When To Sharpen

Sharpen your circular saw blade as soon as it starts to dull. Dull blades struggle to cut cleanly and can burn wood. Signs of dullness include rough edges and slow cutting. Regular sharpening prevents wear and tear. This helps avoid premature replacement.

When To Replace

Replace your circular saw blade if sharpening no longer improves performance. Inspect the blade for cracks or missing teeth. These are signs that it’s time to invest in a new one. Always check the blade’s condition before starting any project. A well-maintained blade ensures safety and precision.

Choosing The Right Blade For The Job

Selecting the right blade ensures efficiency. A circular saw blade typically lasts between 12 to 120 hours, depending on usage and material. Proper maintenance extends its lifespan.

Choosing the right blade for your circular saw is crucial for both performance and longevity. The type of blade you use can significantly impact how long it lasts and how well it cuts through different materials. It’s not just about picking any blade off the shelf; you need to match the blade to the task at hand.

Material Compatibility

Different materials require different types of blades. For instance, cutting through hardwood is not the same as cutting through softwood or metal.

Using a blade designed for wood on metal will quickly dull the blade and might even damage it. On the other hand, a blade made for metal will struggle with wood, producing poor cuts and potentially overheating.

Identify the material you’re working with and choose a blade specifically designed for that material. This ensures efficient cuts and extends the life of your blade.

Blade Specifications

Blade specifications are another critical factor. Pay attention to the number of teeth, the blade diameter, and the kerf.

Blades with more teeth generally provide smoother cuts but can wear out faster. Conversely, blades with fewer teeth are more aggressive and durable but may leave rougher edges.

The blade diameter should match your saw’s specifications. A mismatch here can be dangerous and affect the quality of your work.

The kerf, or the width of the cut made by the blade, also matters. A thinner kerf can cut faster and waste less material, but it might be less durable.

Consider these specifications carefully to choose the best blade for your project. This ensures not only safety but also maximizes the blade’s lifespan.

Have you noticed a difference in your blade’s performance when using the right specifications? Share your experiences in the comments!

Safe Operating Practices

Ensuring the longevity of your circular saw blade involves safe operating practices. Proper usage and maintenance not only extend the blade’s life but also ensure your safety. In this section, we will cover some essential practices that will help you use your circular saw blade safely and efficiently.

Correct Cutting Techniques

Using the right cutting techniques is crucial for safe and effective blade operation. Make sure the material is secure before cutting. Use both hands to guide the saw. This ensures better control and accuracy. Avoid forcing the saw through the material. Let the blade do the work. Cutting too fast can damage the blade and the material.

Always cut on a stable surface. An unstable surface can cause uneven cuts and accidents. Wear safety gear, such as goggles and gloves, to protect yourself. Keeping a steady pace and following the cut line will help maintain the blade’s sharpness and precision.

Preventing Overheating

Overheating can significantly reduce the lifespan of your circular saw blade. To prevent this, avoid prolonged cutting sessions. Give the blade time to cool between cuts. Overheating can cause the blade to warp and dull quickly.

Check the blade for any signs of overheating, such as discoloration. If you notice any, it’s time to let the blade cool down. Using a blade designed for the material you are cutting also helps. Different materials require different types of blades. A mismatched blade can overheat easily.

Regularly clean the blade to remove resin and debris. This build-up can cause friction, leading to overheating. Keeping your blade clean ensures smoother cuts and a longer lifespan.

Credit: www.darttoolgroup.com

Environmental Considerations

Circular saw blade lifespan depends on environmental considerations. Factors like material, frequency of use, and maintenance impact durability. Proper care ensures longer blade life.

The lifespan of your circular saw blade isn’t solely determined by its use. Environmental factors play a crucial role too. Ignoring these can lead to premature wear and tear.

Impact Of Work Environment

Your work environment has a direct impact on the longevity of your circular saw blade.

If you’re working in a dusty area, particles can accumulate on the blade, leading to quicker dulling. This happened to me while cutting plywood in a home renovation project. The excessive dust reduced the blade’s efficiency within a few days.

Working in a clean and controlled environment can significantly extend the life of your blade. Keeping your workspace tidy and free from debris can make a huge difference.

Temperature And Humidity Effects

Temperature and humidity also affect your saw blade. High temperatures can cause the blade to expand, making it more prone to wear.

Similarly, high humidity levels can lead to rust, which compromises the blade’s integrity. I once left my saw in a humid garage overnight, only to find rust spots the next morning.

Maintaining a stable environment with moderate temperature and low humidity will help preserve your blade.

Are you considering where you store your saw? A dry, cool place is ideal. This small step can save you money in the long run by prolonging your blade’s life.

Credit: www.reddit.com

Frequently Asked Questions

When Should You Replace A Circular Saw Blade?

Replace a circular saw blade when it becomes dull, chipped, or shows signs of rust. Frequent burning or difficulty cutting also indicates the need for replacement. Regularly inspect the blade to ensure optimal performance and safety.

How Many Cuts Does A Circular Saw Blade Last?

A circular saw blade typically lasts between 250 to 1,200 cuts. Blade material and usage affect longevity. Regular maintenance extends its life.

How Often Do Saw Blades Need To Be Replaced?

Saw blades typically need replacement after 1,000 to 2,000 cuts. Factors include material type and usage frequency. Regular inspection ensures optimal performance.

How Do I Know If My Saw Blade Is Bad?

Check for dullness, chipping, or missing teeth. Notice increased resistance, burning wood, or rough cuts. Excessive vibration also indicates a bad blade.

Conclusion

Circular saw blade lifespan varies. Usage and maintenance play key roles. Regular cleaning, proper storage, and correct usage extend blade life. Always check for signs of wear. Replace when needed to ensure safety and efficiency. Keep your tools in top shape for best results.

This helps maintain cutting quality. Happy sawing!